Waterlogged Pressure Tank

Pressure tanks are sometimes confused with holding tanks. The purpose of the pressure tank is not to store water but instead is used to modulate the frequency that the water pump turns on and off. It controls the timing of how quickly the pump starts and stops. This is a very important function for the longevity of the pump.

A waterlogged pressure tank can be very damaging to booster pumps and even more so to submersible pumps. A waterlogged system will cause the rapid cycling of the pump by turning it on and off every few seconds or minutes. This will destroy a pump in a short period of time.

Water well pumps are driven by an electric motor. When an electric motor first turns on it produces the most amount of torque (rotational power). It is like stepping full-throttle on the gas pedal of your car. This generates a lot of electrical heat and the motor quickly becomes very hot.

The function of a pressure tank is to allow the motor to run for a few moments allowing it to cool off. If the pressure tank is waterlogged, the pump motor turns on and off too quickly, resulting no time to cool down and the motor becomes hotter and hotter. High heat breaks down the internal insulation in the pump motor and the motor will fail prematurely.

This is a Computer called a VFD. This unit is NOT to be in the hot sun and should be less than 113 degrees to operate properly.

Does the type of pressure tank make a difference in waterlogging? The easy answer is yes. A galvanized steel tank has three different valves that are used to maintain the ratio of water to air in the tank. Two valves are above ground and the third is in the well but underground. The two above the ground valves are most prone to malfunction and require periodic maintenance and/or replacement. This should be done about once a year or so depending on the hardness of the water. Galvanized pressure tanks require a little more maintenance.

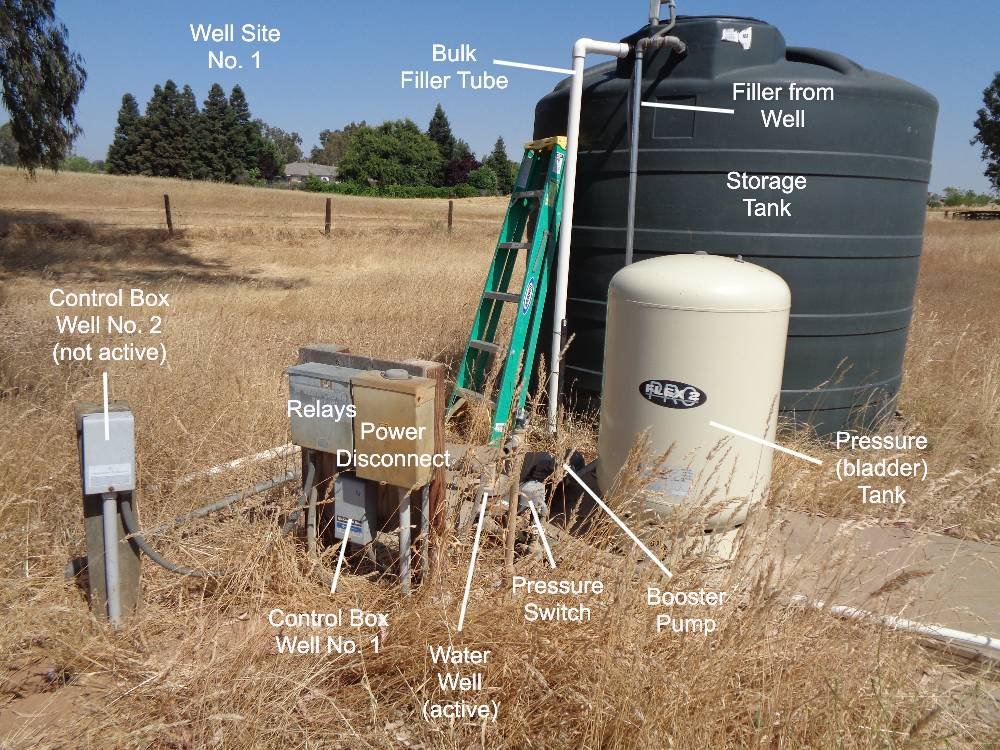

Unusual Storage Tank System, poorly maintained.

The newer type of pressure tanks, bladder tanks, are less likely to waterlog. A bladder tank has an intertube type device on the inside. A bladder separates the air from the water. These tanks also require periodic maintenance but of a different kind. The pressure inside the bladder tank has some very specific requirements and can only be measured with the total water system at zero pressure. The adjustment is based on the preferred lower limit of the operating pressure. This adjustment is better handled by a “Master Installer” that understands the operational needs of the system and should be done at least every two years.

If the bladder tank has zero pressure at the same time the system has zero pressure, this means the internal rubber membrane of the bladder tanks has failed. There is no way to repair a ruptured membrane and the bladder tank needs to be replaced.

For more information or if you have any questions, just call Tom at Kings River Drilling & Pump Service. The advice is free. So call someone you can trust.